We provide structural vibration monitoring and shock detection solutions for more than 17,000 wind turbines annually with more than 130,000 active installations as of 2021. The PCH1026 is a PL-d / GL2010 certified 3-directional structural vibration monitors provide alarm/danger alerts, sudden shock detection as well as real-time filtered.

ISO 10816-3 was prepared by Technical Committee ISO/TC 108, Mechanical vibration, shock and condition monitoring, Subcommittee SC 2, Measurement and evaluation of mechanical vibration and shock as applied to machines, vehicles and structures. The ISO 10816-3 standard provides criteria for evaluating the vibration of machinery according to measurements taken on non-rotating parts, such as bearings, bearing pedestals, or housings. It serves as a general guideline for determining overall machine condition based on the magnitude of vibration and changes in vibration levels over time.

Why ISO 10816 is important for vibration measurement engineers?

General Machines

Steam Turbine and Generators

generators over 50 MW & rotational speeds from 1500 to 3600 RPM

Critical Machines

by accelerometer or velocity transducers on fixed parts like bearing housings

Gas Turbines

NOT: These Values, Which are the upper limits of zone A,B and C Respectively, Should apply to radial vibration measurements on all bearing housings or pedestals and to axial vibration measurements on housings containing an axial thrust bearing, under steady-state operating conditions at rated speed.in this figure shows typical measurement positions.

Hydro Turbine

Reciprocating Machinery

ISO 10816-6 specifies the general conditions and procedures for the measurement and evaluation of vibration, using measurements made on the non-rotating and non-reciprocating parts of reciprocating machines. It generally applies to reciprocating piston machines mounted either rigidly or resiliently with power ratings of above 100 kW. Typical examples of application are: marine propulsion engines, marine auxiliary engines, engines operating in diesel generator sets, gas compressors and engines for diesel locomotives. The general evaluation criteria which are presented relate to both operational monitoring and acceptance testing. They are also used to ensure that the machine vibration does not adversely affect the equipment directly mounted on the machine.

Pump

ISO 10816-7 gives instructions for the evaluation of vibration on rotary pumps for industrial applications with nominal power above 1 kW. It defines the special requirements for evaluation of vibration when the vibration measurements are made on non-rotating parts (bearing housing vibration). It provides specific guidance for assessing the severity of vibration measured on bearing housings of rotary pumps in situ and for the acceptance test at the manufacturer’s test facility or in the plant.

This part of ISO 10816 also gives general information and guidelines for assessing relative shaft vibration of the rotating shaft.

This part of ISO 10816 specifies zones and limits for the vibration of horizontal and vertical pumps irrespective of their support flexibility. Additionally, recommendations are given for defining operational limits and setting alarm and trip values.

Reciprocating Compressors

- horizontal, vertical, V-, W-, and L-type compressor systems,

- compressors driven by electric motors, gas, and diesel engines, steam turbines, with or without a gearbox, flexible or rigid coupling, and

- dry running and lubricated reciprocating compressors.

Onshore wind turbines with gearbox

Disclaimer: The author is not trying to present himself as an authority on all available CM standards. This blog post is simply an attempt to help those who may be unaware that such guidance exists or of the extent of such standards.

We previously introduced a series of international standards pertaining to condition monitoring of industrial equipment with vibration analysis in, This series ends with the numeric sequence of xx816-x. The original standards from 1974 (ISO 2372) and 1985 (ISO 3945) were replaced or superseded by ISO 10816-1 in 1995. 10816-1 was amended in 2009 and then replaced by ISO 20816-1 in 2016. Next (numerically) is the standard we also mentioned in our previous blog, 20816-2. The dash 2 standard covers the measurement and evaluation of vibration on large land-based gas or steam turbines and generators.

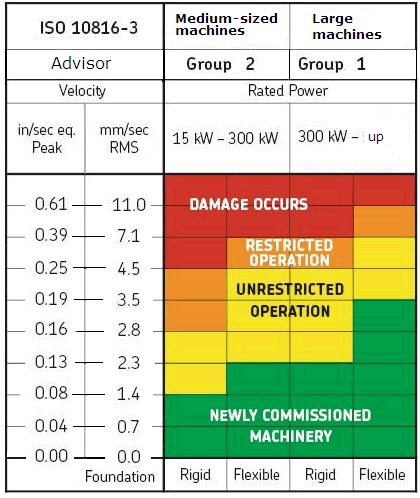

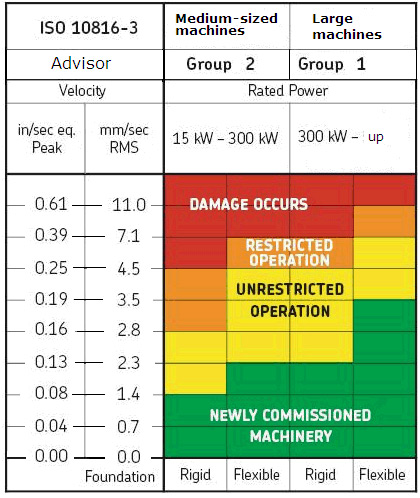

The subsequent standard in the series, the “dash 3” standard is the focus of this blog. This standard is titled:

Vibration Standard Iso 10816-3 -

INTERNATIONAL STANDARD ISO 10816-3

Mechanical vibration — Evaluation of machine vibration by measurements on non-rotating parts

Iso 10816 1

Part 3: Industrial machines with nominal power above 15 kW and nominal speeds between 120 r/min and 15 000 r/min when measured in situ

ISO 10816-3 is the current standard in the series that covers a general range of equipment types and sizes. When first created it was the “catch-all” standard used for many types of machines (such as centrifugal pumps which are now covered by the dash 7 standard) that have since come to be covered by their own specific part of the series. The “10816” issuance of the dash 3 standard is still in force, but to be current it must be joined by a 2017 amendment, “Amendment 1”. This amendment actually modifies the scope of the standard, so it is critical to its being considered current.

The scope of this standard is quoted below from the ISO.org preview page (quotation in bold).

Important Note: The scope shown in the preview cannot be considered current because it is modified by Amendment 1.

Scope:

Iso 10816 3 2014 Free

This part of ISO 10816 gives criteria for assessing vibration levels when measurements are made in situ. The criteria specified apply to machine sets having power above 15 kW and operating speeds between 120 r/min and 15 000 r/min.

The machine sets covered by this part of ISO 10816 include:

- steam turbines with power up to 50 MW

- steam turbine sets with power greater than 50 MW and speeds below 1 500 r/min or above 3 600 r/min (not included in ISO 10816-2)

- rotary compressors

- industrial gas turbines with power up to 3 MW

- generators

- electrical motors of any type

- blowers or fans

Iso 10816 3 Pdf

NOTE: However, the vibration criteria presented in this part of ISO 10816 are generally only applicable to fans with power ratings greater than 300 kW or fans that are not flexibly supported. As and when circumstances permit, recommendations for other types of fans, including those with lightweight sheet metal construction, will be prepared. Until such time, classifications can be agreed upon between the manufacturer and the customer, using results of previous operational experience, see also ISO 14694[4].

The following are excluded from this part of ISO 10816:

- land-based steam turbine generator sets with power greater than 50 MW and speeds of 1 500 r/min, 1 800 r/min, 3 000 r/min, or 3 600 r/min (see ISO 10816-2)

- gas turbine sets with power greater than 3 MW (see ISO 10816-4)

- machine sets in hydraulic power generating and pumping plants (see ISO 10816-5)

- machines coupled to reciprocating machines (see ISO 10816-6)

- rotodynamic pumps including integrated electric motors, i.e. where the impeller is mounted directly on the motor shaft or is rigidly attached to it (see ISO 10816-7)

- rotary positive displacement compressors (e. g. screw compressors)

- reciprocating compressors

- reciprocating pumps

- submerged motor-pumps

- wind turbines

Vibration Standards Iso 10816-3

The criteria of this part of ISO 10816 apply to in situ broad-band vibration measurements taken on the bearings, bearing pedestals, or housing of machines under steady-state operating conditions within the nominal operating speed range. They relate to both acceptance testing and operational monitoring. The evaluation criteria of this part of ISO 10816 are designed to apply to both continuous and non-continuous monitoring situations.

Vibration Standard Iso 10816-3 Pdf Free Download

This part of ISO 10816 encompasses machines that may have gears or rolling element bearings but does not address the diagnostic evaluation of the condition of those gears or bearings.

Iso 10816 1 Pdf

The criteria are applicable only for the vibration produced by the machine set itself and not for vibration which is transmitted to the machine set from external sources.

To read the ISO’s preview of this standard, click here.

Comments are closed.